Store Stock Redistribution supports different strategies to calculate the trips between the store and/or warehouse locations to redistribute items.

The Redist. Strategies are different calculation methods to find the best possible combination of locations to fulfill the demand in the store locations. Only locations that are set up in the Redist. Matrix are considered in the calculation. The consideration of warehouse locations can be parametrized and allows different scenarios.

Supported strategies:

- Least No of Trips

- Least Cost

- Shortest Distance (Direct)

- Shortest Distance (Route)

- Shortest Duration (Route)

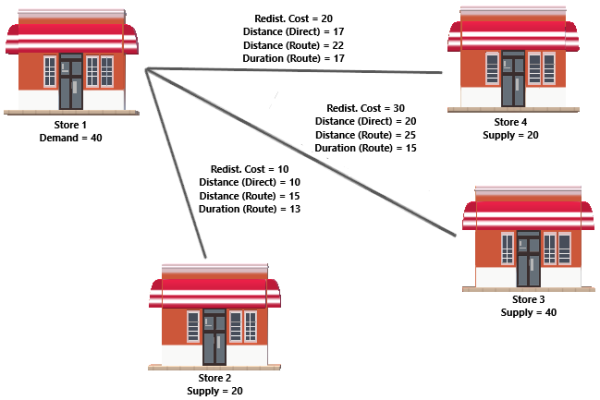

Calculation example

In the above example, Store 1 has an item demand of 40 quantities, and Store 2, Store 3, and Store 4 have the supply of 20, 40 and 20 quantities, respectively, for the same item. The Redist. Cost, Distance (Direct), Distance (Route), and Duration (Route) from the respective stores to Store 1 are as mentioned in the example. Now, out of all the possible options to choose from, the system tries to choose the best fitting Store(s) to get the supply from, using the Redist. Strategy defined.

Strategy: Least No. of Trips

This Redist. Strategy prioritizes the supply stores based the highest stock available for redistribution, which helps the system to generate the minimum trips required to fulfill the demand. In the above example, Store 3 has the highest stock, followed by Store 2 and Store 4. Now, neither Store 2 nor Store 4 has the supply to fulfill the demand at one go. So, choosing any one of them will incur two trips to fulfill the demand of Store 1. However, there is Store 3, for which the supply is enough to fulfill the demand of Store 1 within a single trip. Therefore, using the Least No. of Trips Redist. Strategy for the above example, the system will choose Store 3 as the best fitted store to supply the 40 quantities to Store 1.

Strategy: Least Cost

This Redist. Strategy prioritizes the supply stores based on the Redist. Cost incurred for the route. In the above example, the route from Store 2 to Store 1 incurs the lowest Redist. Cost, followed by Store 4, and finally, Store 3. Therefore, using the Least Cost Redist. Strategy for the above example, the system will first choose Store 2 to supply the 20 quantities to Store 1. However, as Store 2 cannot fulfill the whole demand for Store 1, the system will then look for the next store with the lowest cost, which is Store 4, which fulfills the remaining demand of 20 quantities for Store 1. Therefore, the best fitted stores for supply in this case are Store 2 and Store 4 combined.

Strategy: Shortest Distance (Direct)

This Redist. Strategy prioritizes the supply stores based on Direct Distance between the stores. In the above example, in terms of Direct Distance, Store 2 is nearest to Store 1, followed by Store 4, and finally, Store 3. Therefore, using the Shortest Distance (Direct) Redist. Strategy for the above example, the system will first choose Store 2 to supply the 20 quantities to Store 1. However, as Store 2 cannot fulfill the whole demand for Store 1, the system will then look for the next store with the shortest Direct Distance, which is Store 4, which fulfills the remaining demand of 20 quantities for Store 1. Therefore, the best fitted stores for supply in this case are Store 2 and Store 4 combined.

Strategy: Shortest Distance (Route), Shortest Duration (Route)

These Redist. Strategies prioritize the supply stores based on Route Distance and Route Duration between the stores.

In the above example, in terms of Route Distance, Store 2 is nearest to Store 1, followed by Store 4, and finally, Store 3. Therefore, using the Shortest Distance (Route) Redist. Strategy for the above example, the system will first choose Store 2 to supply the 20 quantities to Store 1. However, as Store 2 cannot fulfill the whole demand for Store 1, the system will then look for the next store with the shortest Route Distance, which is Store 4, which fulfills the remaining demand of 20 quantities for Store 1. Therefore, the best fitted stores for supply in this case are Store 2 and Store 4 combined.

Alternatively, in terms of Route Duration, the route between Store 2 to Store 1 is the fastest, followed by Store 3, and finally, Store 4. Therefore, using the Shortest Duration (Route) Redist. Strategy for the above example, the system will first choose Store 2 to supply the 20 quantities to Store 1. However, as Store 2 cannot fulfill the whole demand for Store 1, the system will then look for the next store with the fastest Route Duration, which is Store 3, which fulfills the remaining demand of 20 quantities for Store 1. Therefore, the best fitted stores for supply in this case are Store 2 and Store 3 combined.

| To | See |

|---|---|

| Learn more about the strategy Least No. of Trips. | Least No of Trips |

| Learn more about the strategy Least Cost. | Least Cost |

| Learn more about the strategy Shortest Distance (Direct). | Shortest Distance (Direct) |

| Learn more about the strategies Shortest Distance (Route) and Shortest Duration (Route). | Shortest Distance (Route) |

Note: Warehouse locations are treated differently than store locations in the calculation - for more information click here.

See Also